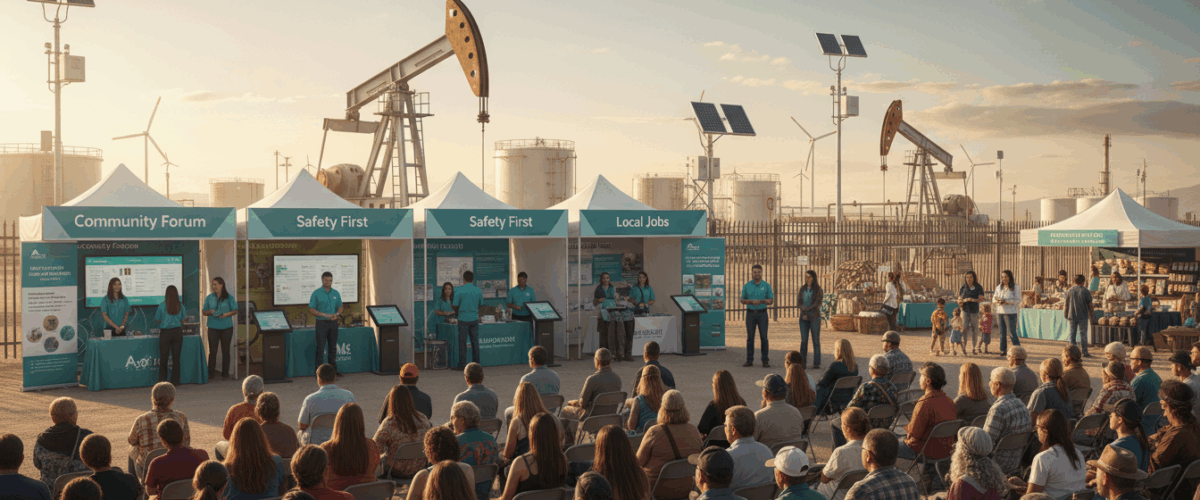

Onshore energy projects, from oil and gas developments to renewable energy installations, often sit close to towns, farms, and communities whose daily lives are affected by industrial activity. For project developers, community engagement is not just a social obligation; it is a core business strategy. Effective engagement helps secure local support, reduce risks of delays or opposition, and create lasting value for both companies and communities. Around the world, several successful models demonstrate how thoughtful community relations can turn potential conflicts into partnerships.

Why Community Engagement Matters

Energy projects can bring jobs, infrastructure, and revenue, but they can also disrupt traditional livelihoods, strain local resources, or trigger environmental concerns. When communities feel excluded or ignored, resistance often follows—leading to costly disputes, legal battles, and reputational damage. By contrast, proactive engagement builds trust, ensures transparency, and fosters shared ownership of outcomes.

Successful Engagement Models from Onshore Projects

- Participatory Planning in Norway’s Oil Sector

Norway has long been cited as a model for balancing energy development with community interests. The government requires early consultations with local stakeholders before project approvals. Municipalities and residents are invited to participate in planning processes, ensuring that projects align with regional needs. This approach has built broad public trust in the country’s onshore petroleum operations. - Local Content and Employment in Nigeria

In Nigeria, community engagement has historically been challenging in oil-producing regions. However, successful projects increasingly integrate “local content” policies, ensuring that local workers and contractors benefit from operations. Training programs, employment quotas, and supplier development initiatives have improved relationships between companies and host communities, reducing conflict and improving livelihoods. - Benefit-Sharing in Canada’s Indigenous Partnerships

Onshore oil, gas, and renewable projects in Canada often cross Indigenous lands. Successful developers have established equity partnerships, revenue-sharing agreements, and long-term job creation strategies with Indigenous communities. These models go beyond one-off compensation, creating sustainable benefits and empowering local governance. Projects like the Coastal GasLink pipeline have illustrated both the challenges and potential of this approach. - Transparency and Dialogue in Colombia

In Colombia, oil and mining companies have faced opposition over land and environmental concerns. Some firms have adopted open communication strategies, publishing project data, holding town halls, and establishing grievance mechanisms. By prioritizing dialogue and transparency, these projects have fostered stronger community relationships, reducing resistance and improving social license to operate. - Sustainable Development Projects in the Middle East

In parts of the Middle East, energy companies have successfully engaged communities by funding local development projects—such as schools, health clinics, and water supply systems. These initiatives address immediate community needs, while also strengthening the long-term reputation of the operator. Aligning projects with broader national development goals has proven especially effective.

Key Lessons Across Models

Successful engagement is not about a single formula, but about principles that apply globally:

- Early and continuous involvement: Engaging communities before project design and maintaining dialogue throughout builds trust.

- Transparency: Openly sharing information about environmental, social, and economic impacts helps manage expectations.

- Local benefit: Jobs, training, and infrastructure investments create tangible value that communities can see.

- Cultural respect: Recognizing local traditions, governance systems, and concerns ensures projects are context-sensitive.

- Partnership, not charity: Moving from transactional compensation to long-term collaboration creates mutual success.

Community engagement in onshore projects is no longer a secondary concern; it is central to project success. From Norway to Nigeria, Canada to Colombia, and the Middle East, the most successful models demonstrate that when companies treat communities as partners, they reduce risks, improve outcomes, and create lasting shared value. As the global energy sector evolves, embedding community voices into project design and operation will remain a critical factor in achieving both commercial and social success.

Read more on Sparkview Energy:

Community Engagement and Social Responsibility in Oil and Gas Operations

Crisis Management in Midshore Operations: Planning for the Unexpected

Balancing Community Interests with Onshore Oilfield Development